Aerospace Tooling

Fisher Cast Steel has a long history of casting components for the commercial and government aircraft tooling industry. Parts cast are used to form, heat treat or fixture for the aircraft manufacturing process. Fisher has supplied tooling to many of the world’s largest aerospace manufacturers and government entities.

Fisher Cast Steel has a long history of casting components for the commercial and government aircraft tooling industry. Parts cast are used to form, heat treat or fixture for the aircraft manufacturing process. Fisher has supplied tooling to many of the world’s largest aerospace manufacturers and government entities.

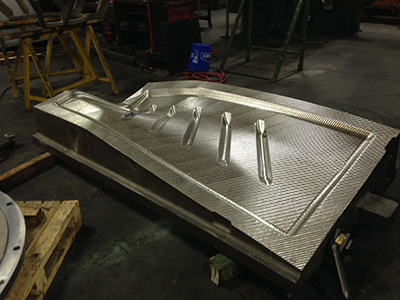

Forming tools such as super plastic forming dies (SPF), hot forming dies (HFD), press platens, low expansion, heat treat and other aerospace fixtures are cast at Fisher. We have the ability to pour and heat treat a wide range of alloys and sizes. Fisher’s on-time delivery and first class quality is essential to our customer base.

Fisher works directly with tooling engineers to design the mostly effective part for each application. In tandem with Solidworks CAD and MAGMASOFT simulation software, Fisher can help bridge rough design to finished part. Our experience with the various methods of casting, give us the ability to help our customer choose the best option.

Materials poured at Fisher Cast Steel include nearly all heat-resistant and high temperature alloys that allow tooling to perform over multiple uses. Commonly used materials include ASTM A297 HN, Modified HN, HT, HP, HU, Invar 36, Cobalt/Stellite, Inconel, low expansion, corrosion and abrasion resistant, and tool steels are cast as well. See a complete list of alloys poured.

Casting sizes range from 1 – 8,500 lbs. Fisher has in-house NDT capabilities to ensure parts meet required specifications.